Supply Chain Resilience in Due Diligence - Building Operational Robustness

Learn how buyers assess supply chain risks during due diligence and discover frameworks for demonstrating operational resilience through supplier diversification

The semiconductor shortage that constrained automotive production during 2021, with industry analysts estimating millions of vehicles delayed, didn’t just disrupt supply chains. It fundamentally rewired how acquirers evaluate operational risk. Sophisticated buyers learned expensive lessons about sourcing vulnerability, and in the current post-pandemic environment, they’re applying that hard-won wisdom to acquisition targets they assess.

Executive Summary

Supply chain resilience has emerged as a meaningful due diligence focus area in today’s M&A landscape. Buyers who once glossed over vendor relationships now deploy specialized teams to evaluate sourcing concentration, geographic dependencies, and supplier financial health. For business owners planning exits within the next two to seven years, this shift demands proactive attention to supply chain documentation and diversification strategies, particularly for manufacturing and distribution businesses with physical supply chains.

The stakes matter, though quantifying them involves significant uncertainty. Based on our experience reviewing transactions and conversations with M&A advisors, companies demonstrating robust supply chain resilience appear to support stronger valuations compared to peers with concentrated sourcing risks. However, we cannot point to transaction databases proving a specific premium percentage, and the impact varies substantially by industry, buyer type, and specific deal circumstances. What we can say is that discovered vulnerabilities during due diligence frequently trigger purchase price reductions, expanded escrow requirements, or increased buyer negotiating leverage.

This article examines the specific supply chain factors buyers evaluate during due diligence, explains the assessment methodologies sophisticated acquirers employ, and provides actionable frameworks for demonstrating operational robustness. Whether you source from three suppliers or three hundred, understanding how buyers perceive and price supply chain risk positions you to address vulnerabilities while minimizing transaction friction.

The businesses that thrive through due diligence aren’t necessarily those with perfect supply chains: they’re the ones that demonstrate awareness of their vulnerabilities and credible plans for managing them.

Introduction

Consider a scenario that has become increasingly common in today’s M&A environment: a private equity firm evaluating a regional food manufacturer discovers during due diligence that the target sources more than 70% of its primary ingredients from a single supplier. This concentration risk, regardless of how reliable that supplier has been historically, creates uncertainty that buyers must factor into their offers, often resulting in purchase price discussions that differ from initial expectations.

This scenario reflects a shift in buyer priorities that emerged after 2020. Before the pandemic, supply chain due diligence typically amounted to verifying that major vendor contracts existed and checking for obvious single-source dependencies. Today’s sophisticated acquirers, particularly private equity firms, approach supply chain assessment with greater rigor, recognizing that supply chain disruptions can affect acquired businesses faster than many balance sheet issues.

The pandemic exposed vulnerabilities that many business owners had accepted as normal. Geographic concentration in manufacturing regions that experienced lockdowns. Just-in-time inventory strategies that provided no buffer against shipping delays. Supplier relationships built on handshakes rather than documented agreements with performance standards and continuity provisions.

Industry reports support this directional shift. Organizations have generally improved their approach to supply chain risk assessment since 2020, with executives across industries indicating increased focus on supply chain visibility and resilience. While specific survey percentages vary and we cannot cite a single authoritative source, the trend appears consistent across multiple industry analyses.

For business owners contemplating exits, this evolution creates both challenges and opportunities. The challenge lies in meeting elevated scrutiny standards that didn’t exist five years ago. The opportunity emerges from differentiation: sellers who demonstrate supply chain resilience stand out and address buyer concerns proactively.

What Buyers Actually Evaluate During Supply Chain Due Diligence

Understanding buyer methodology helps you prepare effectively. Modern supply chain due diligence examines multiple risk dimensions, each with specific documentation requirements and evaluation criteria. Note that due diligence intensity varies significantly by buyer type: private equity firms focused on operational improvements typically scrutinize supply chain more intensively than strategic buyers acquiring primarily for customer relationships or market access.

Supplier Concentration Analysis

Buyers calculate concentration metrics across several dimensions. The most common measure examines what percentage of total procurement spend flows to your top five suppliers. Based on our experience reviewing due diligence files and conversations with M&A professionals, acquiring companies often express concern when any single supplier represents more than 20-30% of total spend or when the top five suppliers collectively exceed 50-65%. These thresholds vary considerably by industry, buyer sophistication, and specific circumstances. We present these ranges as directional guidance rather than industry standards.

Beyond spend concentration, sophisticated buyers evaluate revenue dependency: the percentage of your sales that would be at risk if specific suppliers failed. To illustrate with a hypothetical example: a manufacturer might source only 8% of total procurement from a specialized component supplier, but if that component appears in products representing 45% of revenue, the true concentration risk far exceeds the spend percentage. This revenue dependency calculation often reveals risks that spend analysis alone would miss.

Geographic concentration receives similar scrutiny. Buyers map supplier locations to identify regional clustering that could create simultaneous disruption risk. A business sourcing from fifteen different suppliers might appear diversified until due diligence reveals that twelve of those suppliers operate facilities within fifty miles of each other in a region prone to hurricanes or earthquakes.

Supplier Financial Health Assessment

Buyer due diligence teams increasingly evaluate the financial stability of critical suppliers. They recognize that your supply chain is only as strong as its weakest link. A supplier bankruptcy or sudden closure can halt your operations regardless of how well-managed your internal processes appear.

Expect buyers to request financial information about your top suppliers or, at minimum, documentation showing that you monitor supplier financial health. This might include credit reports, Dun & Bradstreet ratings, or evidence of regular financial review processes. Sophisticated buyers may view supplier financial monitoring as an indicator of operational maturity: companies that track supplier health demonstrate awareness of supply chain risk, though documentation alone doesn’t substitute for actual supplier stability.

For privately held suppliers where financial information isn’t available, buyers look for alternative indicators of stability: longevity in business, ownership structure, customer diversification, and your historical relationship patterns. A twenty-year supplier relationship with consistent performance tells a different story than a two-year relationship that replaced a failed vendor.

Contractual Protection Evaluation

Documentation quality significantly influences buyer perception of supply chain resilience. Acquirers examine not just whether supplier contracts exist, but whether those agreements include provisions that protect operational continuity.

Key contractual elements buyers evaluate include:

Term and termination provisions that ensure supply continuity through reasonable notice periods. Month-to-month arrangements or contracts terminable on thirty days’ notice create uncertainty that buyers must consider in their offers.

Volume commitment structures that guarantee supply access. Agreements specifying that you represent a certain percentage of supplier capacity, or that grant priority status during allocation situations, demonstrate supply security.

Quality standards and remediation processes that protect against defective inputs. Buyers want evidence that supplier quality issues won’t flow through to your customers and damage the business reputation they’re acquiring.

Business continuity requirements obligating suppliers to maintain disaster recovery capabilities, insurance coverage, and backup production arrangements. These provisions demonstrate that you’ve considered and addressed supplier failure scenarios.

Change of control provisions that ensure supply relationships survive your exit transaction. Buyers seek confidence that their acquisition won’t trigger supplier contract terminations, though the frequency of such terminations varies significantly by industry and relationship history.

Operational Resilience Indicators

Beyond supplier-specific analysis, buyers evaluate systemic resilience indicators that suggest how your business would perform during supply disruptions.

Inventory strategy receives significant attention. Pure just-in-time models that minimize working capital also minimize buffer against supply interruptions. Buyers assess whether inventory levels reflect considered risk management or simply cash conservation. Companies maintaining strategic safety stock of critical components demonstrate operational awareness that buyers value.

Substitute sourcing capability matters considerably. Can you shift production to alternative materials if primary inputs become unavailable? Have you qualified backup suppliers who could ramp quickly if needed? Buyers view qualification processes, even for suppliers you don’t actively use, as evidence of resilience planning, though qualification doesn’t guarantee availability during actual crises.

Internal capabilities that reduce supplier dependency also factor into assessments. Vertical integration, whether partial or complete, reduces external sourcing risk. Even capabilities like in-house tooling maintenance or the ability to produce certain components internally during emergencies demonstrate operational flexibility.

Assessment Methodologies Sophisticated Buyers Employ

Understanding buyer assessment methodologies helps you anticipate questions and prepare documentation that addresses likely concerns proactively. Note that assessment rigor varies significantly: large PE firms and sophisticated strategic acquirers typically employ formal frameworks, while smaller buyers may conduct less structured evaluations.

Quantitative Risk Scoring

Many larger acquirers employ standardized scoring frameworks that quantify supply chain risk across multiple dimensions. These frameworks vary by buyer, but a typical approach might evaluate factors including:

| Risk Dimension | Typical Weight Range | Assessment Criteria |

|---|---|---|

| Supplier Concentration | 20-30% | Spend distribution across supplier base |

| Geographic Concentration | 15-25% | Location clustering and regional risk factors |

| Financial Stability | 15-25% | Supplier creditworthiness and longevity |

| Contractual Protection | 10-20% | Agreement quality and continuity provisions |

| Substitute Availability | 10-15% | Qualification of alternative sources |

| Historical Performance | 5-15% | Track record of supply disruptions |

These frameworks produce composite risk scores that buyers compare against industry benchmarks and their own portfolio companies. Understanding that such quantitative analysis may occur helps you prepare supporting documentation that addresses each dimension directly.

Scenario Analysis and Stress Testing

Some sophisticated buyers conduct scenario analyses that model how your business would perform under various supply disruption scenarios. Common scenarios include:

Single supplier failure: What happens if your largest supplier ceases operations? How quickly could you source alternatives? What would the revenue impact be during transition?

Regional disruption: If a natural disaster affected the geographic region where your suppliers concentrate, how long could you operate on existing inventory? What backup arrangements exist?

Quality crisis: If a critical supplier delivered defective inputs that reached customers, what would the detection timeline be? What remediation processes exist? What’s your liability exposure?

Demand surge: If you received a major new customer order, could your supply chain scale to meet it? What lead times would be required? Which suppliers represent bottleneck constraints?

Having analyzed these scenarios yourself, and being able to discuss them credibly during due diligence, demonstrates operational sophistication that buyers appreciate. Even if the acquiring buyer doesn’t formally conduct scenario analyses, your preparation signals management capability.

Historical Pattern Analysis

Buyers examine historical supply chain performance to understand how your business has actually managed disruption events. They look for evidence of past supply interruptions, quality issues, or delivery failures, and more importantly, how you responded to those challenges.

A business that experienced a supplier bankruptcy and successfully transitioned to alternative sources within thirty days demonstrates resilience that’s been tested in reality. The experience matters less than the response capability it reveals.

Buyers also analyze patterns in supplier transitions. Companies that change suppliers frequently may signal relationship management problems or quality issues. Conversely, never having changed suppliers might indicate failure to optimize sourcing or concerning dependency on legacy relationships. Context matters significantly in these interpretations: buyer sophistication determines whether they seek to understand the nuances or apply simplistic rules.

Frameworks for Demonstrating Supply Chain Resilience

With clear understanding of buyer evaluation approaches, you can implement frameworks that demonstrate resilience effectively during due diligence. These frameworks apply primarily to manufacturing and distribution businesses with physical supply chains. Software and service businesses may face different dynamics and should adjust recommendations accordingly.

The Tiered Supplier Classification System

Implementing a formal supplier classification system signals operational sophistication while creating documentation structure that supports due diligence. A typical framework classifies suppliers into three tiers:

Tier 1 - Strategic Suppliers: These vendors provide inputs critical to your core product or service delivery. They typically represent significant spend, would be difficult to replace quickly, and warrant the deepest relationship investment. For Tier 1 suppliers, you should maintain detailed files including financial monitoring records, formal contracts with continuity provisions, qualified backup suppliers, and regular business review documentation.

Tier 2 - Important Suppliers: These vendors provide significant inputs but could be replaced with moderate effort if necessary. Tier 2 suppliers warrant formal contracts and periodic relationship management, but may not require the same depth of backup qualification or financial monitoring.

Tier 3 - Transactional Suppliers: These vendors provide commodity inputs readily available from multiple sources. Relationship management can be minimal, though maintaining competitive pricing through periodic rebidding demonstrates procurement effectiveness.

Concentrate your supply chain resilience investment on Tier 1 strategic suppliers: those representing critical inputs or significant spend. For Tier 2 and Tier 3 suppliers, efficient processes suffice; detailed documentation is typically unnecessary. Focus on structural improvements first (diversification, monitoring, and contracts). Documentation supports but doesn’t substitute for actual resilience.

The Resilience Documentation Package

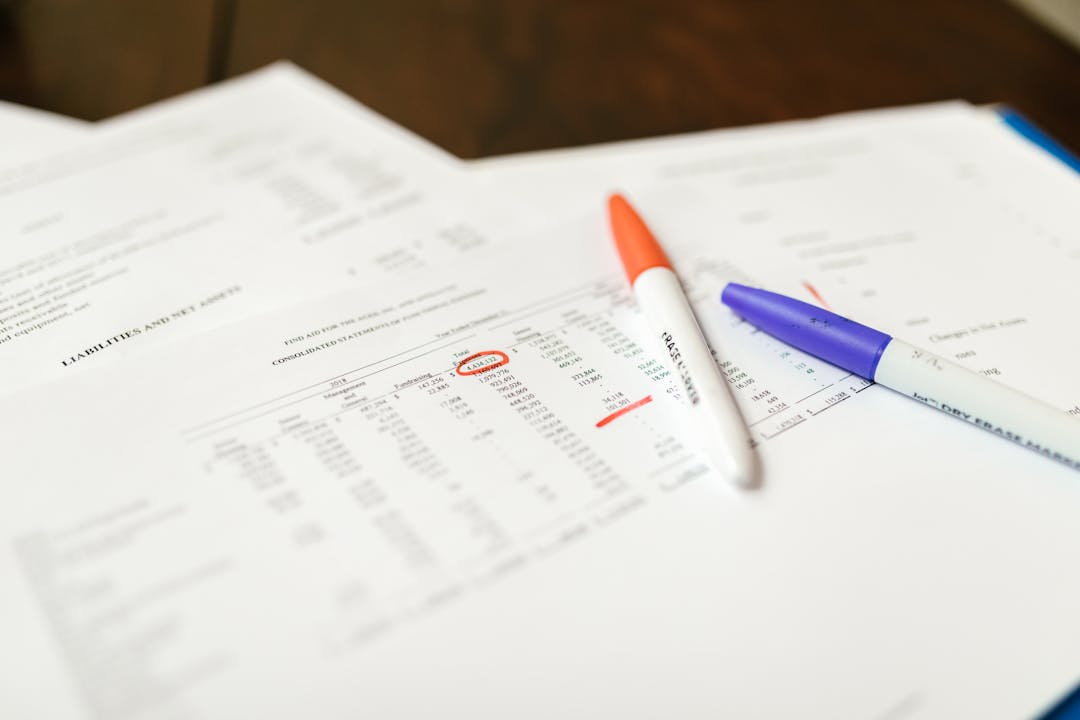

Preparing a supply chain documentation package before entering a sale process can improve due diligence outcomes. This package should include:

Supplier master list with spend data, geographic information, relationship tenure, and tier classification for each vendor. This foundational document speeds response to buyer information requests.

Concentration analysis showing spend distribution, revenue dependency calculations, and geographic mapping. Presenting this analysis proactively, rather than waiting for buyers to calculate it themselves, demonstrates transparency and self-awareness.

Contract summary matrix cataloging key terms for significant supplier agreements including term length, termination provisions, volume commitments, quality standards, and change of control implications.

Backup supplier qualification records documenting alternative sources you’ve identified and qualified for critical inputs, even if you don’t currently purchase from them. Note that qualification doesn’t guarantee availability during actual crises: suppliers may lack capacity when you need them most.

Business continuity documentation describing how your operations would respond to various supplier disruption scenarios, including communication protocols, alternative sourcing activation procedures, and customer notification processes.

Historical incident log recording any significant supply disruptions experienced, how they were managed, and what process improvements resulted. This documentation transforms potential concerns into evidence of tested resilience.

Documentation signals operational sophistication and supports buyer confidence in your process discipline. But documentation is secondary to actual metrics. Prioritize structural improvements before documentation efforts.

The Supplier Relationship Enhancement Program

Beyond documentation, actively strengthening supplier relationships before exit creates tangible resilience improvements that buyers recognize.

Contract improvement: Review agreements with strategic suppliers and negotiate better terms that support business continuity. Even if you can’t achieve perfect contracts, documenting your efforts and any improvements demonstrates proactive risk management. Realistic timeline: begin discussions in the first quarter, but plan for 12-18 months to complete renegotiations with your top ten suppliers, as suppliers may resist changes and demand quid pro quo concessions. In industries with limited supplier alternatives or during supply shortages, negotiations may take 18-36 months or may not be feasible.

Financial monitoring implementation: Establish regular supplier financial health reviews, even if informal. Being able to describe your monitoring process during due diligence matters more than the specific methodology employed.

Backup supplier qualification: Identify and qualify alternative sources for your most critical inputs. For manufacturing applications, qualification typically takes 4-6 months per supplier and includes: RFQ, sample submission, quality testing, capacity verification, and readiness agreement. Service providers may need less time, while specialized technical components may need 9-12 months. For three critical suppliers, plan 12-18 months and budget $3,000-$10,000 per supplier in engineering and quality time. Completing qualification processes, even without placing orders, creates optionality that buyers value, though qualified suppliers may not deliver when you actually need them due to capacity constraints or competing priorities.

Relationship documentation: Record supplier relationship histories, key contacts, and relationship management activities. This institutional knowledge often resides only in employee memories; documenting it protects against knowledge loss and demonstrates operational maturity.

Building Geographic Diversification Into Your Supply Base

Geographic concentration represents one of the most common supply chain due diligence concerns, and one of the most addressable through proactive planning, though with important constraints.

Start by mapping your current supplier geography to identify concentration patterns. Many business owners are surprised to discover the extent of regional clustering in their supply base when they visualize it graphically. Even suppliers with different headquarters may operate production facilities in the same geographic clusters.

Where concentration exists, develop specific diversification plans. This doesn’t necessarily mean changing suppliers immediately, rather, it means identifying alternative sources in different geographic regions and beginning qualification processes. The goal is demonstrating awareness of geographic risk and concrete steps toward mitigation.

Diversification Constraints and Alternatives

For certain inputs, geographic diversification may not be achievable. Some specialized manufacturing concentrates in particular regions for valid reasons including workforce skills, supporting infrastructure, or raw material proximity. For some inputs, especially specialized or highly technical components, there may be only two or three qualified suppliers globally, sometimes clustered in the same region.

Where geographic concentration is unavoidable, compensate through alternative mitigations:

- Increased safety stock of critical components to buffer against regional disruptions

- Advance demand signaling to suppliers that allows them to pre-position inventory

- Contingency plans for extended lead times including customer communication protocols

- Insurance coverage for supply chain interruption where available

In these cases, acknowledge the limitation in your documentation while describing whatever mitigation strategies exist. Buyers appreciate transparency about constraints more than claims of diversification that don’t withstand scrutiny.

Diversification vs. Integration vs. Insurance: Comparing Approaches

Geographic diversification isn’t the only approach to supply chain resilience. For critical inputs, vertical integration, supplier ownership stakes, or insurance represent alternatives worth considering systematically.

Diversification makes sense when:

- Inputs are relatively commoditized and multiple suppliers exist

- Your core competency doesn’t include production of that input

- You have procurement resources to manage multiple relationships

- Industries have sufficient supplier options to make diversification feasible

Tradeoffs: Lower capital investment but requires ongoing supplier management overhead ($25,000-50,000 annually for dual supplier relationships). May increase per-unit costs by 2-8% if moving away from lowest-cost regions. Doesn’t eliminate supplier risk, just distributes it.

Vertical integration makes sense when:

- Inputs represent bottleneck constraints with few alternatives

- Inputs are highly specialized with significant quality variation

- Supplier markup creates substantial margin opportunity

- Your business has capital and expertise to operate production

Tradeoffs: Requires significant capital investment and management attention. Eliminates external supplier risk for that input but creates operational complexity and fixed cost structure.

Minority stake in supplier provides a middle path:

- Some influence and potential supply priority

- Lower capital commitment than full integration

- May provide visibility into supplier operations

Tradeoffs: May not guarantee supply priority during severe shortages. Creates governance complexity and potential conflicts.

Insurance and financial hedging makes sense when:

- Diversification isn’t feasible due to supplier concentration

- Protecting against catastrophic rather than routine disruptions

- Cash flow protection matters more than operational continuity

Tradeoffs: Doesn’t address operational continuity during disruptions. May have coverage gaps or claim disputes. Protects financially but doesn’t maintain customer service.

For most mid-market companies, diversification combined with safety stock represents the most practical strategy. But if you’re evaluating substantial capital investment in supply chain resilience, consider whether that capital might be better deployed toward integration of truly critical inputs.

Which Buyers Care About Your Supply Chain?

Supply chain due diligence intensity varies significantly by buyer type, and understanding this variation helps you calibrate your investment in resilience improvements appropriately.

Private equity buyers typically care most about supply chain resilience. Their investment thesis often depends on operational improvement and EBITDA growth, making supply chain risk a direct threat to returns. PE firms also hold portfolio companies for defined periods, creating urgency around operational stability. Expect rigorous supply chain evaluation from PE acquirers: these buyers often deploy specialized operational due diligence teams.

Strategic buyers acquiring for operational synergies care significantly, as they’re often planning to integrate your operations with their own supply chain. They’ll evaluate compatibility and redundancy potential. But they may view your current supply chain as temporary if they plan to migrate operations to their infrastructure.

Strategic buyers acquiring for customer relationships or market access may care less about your specific supply chain, particularly if they plan to migrate your operations onto their existing infrastructure. In these cases, supply chain resilience may be less important than customer retention, market position, or proprietary technology.

Smaller regional buyers often lack the due diligence resources to conduct sophisticated supply chain analysis, though awareness is increasing across buyer categories.

Adjust your supply chain investment based on your likely buyer profile. If you’re building toward a PE exit, supply chain resilience deserves significant attention. If you’re likely to be acquired by a strategic buyer primarily interested in your customer base or technology, other factors may warrant higher priority. Understanding your probable buyer type before investing heavily in supply chain improvements can prevent misallocated preparation resources.

Understanding the Valuation Impact and Its Limitations

Supply chain resilience contributes to valuation through multiple mechanisms, though quantifying the exact impact requires acknowledging significant uncertainty. We want to be direct about what we can and cannot claim.

What we can say with confidence:

- Discovered supply chain vulnerabilities during due diligence create buyer leverage that typically manifests in price negotiations, expanded escrow requirements, or representation and warranty provisions

- Demonstrable resilience addresses buyer concerns proactively, reducing negotiating friction

- Companies with strong supply chains signal operational maturity that builds buyer confidence

What we cannot prove:

- A specific percentage premium that supply chain resilience commands

- Transaction database evidence showing measurable valuation differences

- That supply chain investments alone will improve your exit outcome

The correlation between supply chain quality and valuation involves significant confounding factors: companies with strong supply chains often excel in other operational areas as well. A business with excellent supplier relationships typically demonstrates strong vendor management, quality processes, and operational discipline that affect valuation through multiple channels.

Mechanisms through which resilience may support valuation:

Reduced buyer risk perception: Buyers discount purchase prices for perceived operational risk. Demonstrable supply chain resilience reduces this risk perception, which may support higher valuations, though the magnitude varies based on buyer risk tolerance and industry norms.

Working capital efficiency: Well-managed supply chains often require less working capital through optimized inventory levels. Since most transactions are structured on a cash-free, debt-free basis with working capital adjustments, efficiency here directly impacts seller proceeds.

Customer retention confidence: Buyers evaluate the risk that supply chain issues could damage customer relationships post-acquisition. Demonstrated resilience supports confidence in customer retention.

Integration cost reduction: For strategic buyers, a well-documented supply chain reduces integration cost estimates, potentially improving deal terms.

When Supply Chain Resilience Doesn’t Drive Valuation

Supply chain improvements don’t guarantee valuation improvements. Supply chain resilience supports valuation when it addresses specific buyer concerns, but it’s one of many factors buyers evaluate.

If the buyer’s primary concern is growth trajectory, profitability, management team retention, or customer concentration, supply chain excellence alone won’t move the valuation needle significantly. A company with excellent supply chain resilience but declining revenue will still face valuation pressure.

Similarly, we’ve observed acquisitions where companies with average supply chains achieved strong valuations because buyers valued other attributes more highly, particularly unique technology, strong customer relationships, or exceptional growth rates.

The implication: supply chain work should complement, not substitute for, addressing more fundamental value drivers. If your growth story is weak or your profitability is below industry norms, those issues warrant attention before supply chain optimization.

Realistic Cost-Benefit Considerations

Before investing heavily in supply chain resilience, consider the full costs and realistic timeline to realize benefits.

Estimated investment requirements:

| Investment Area | Initial Cost | Ongoing Annual Cost | Timeline |

|---|---|---|---|

| Supplier concentration audit | 40-80 hours internal time or $10,000-$25,000 external | $5,000-$10,000 maintenance | 2-4 months |

| Backup supplier qualification (per supplier) | $3,000-$10,000 in engineering/quality time | $10,000-$15,000 recurring qualification | 4-12 months depending on complexity |

| Contract renegotiation (10 suppliers) | 100-200 hours management/legal time | Minimal if terms are stable | 12-18 months typical, 24+ months in concentrated industries |

| Geographic diversification | May increase per-unit costs 2-8% | Dual supplier management: $25,000-$50,000 annually | 12-24 months |

| Documentation and monitoring systems | 60-100 hours initial setup | 20-40 hours annually | 2-3 months |

| Additional inventory carrying costs | Varies by inventory levels | $30,000-$60,000 annually for safety stock | Immediate |

Full cost accounting over a 3-year period:

- Initial investments: $50,000-$150,000

- Ongoing annual costs: $80,000-$150,000

- 3-year total: $290,000-$600,000

Risk-adjusted benefit analysis: The honest answer is that we cannot provide a reliable ROI calculation because we cannot prove the valuation premium. What we can say is that these investments make the most sense when:

- Exit timeline is 2-5 years (enough time to implement but not so long that conditions change dramatically)

- Likely buyers are PE firms or operationally-focused strategic acquirers

- Current supply chain has identifiable, addressable vulnerabilities that would clearly concern buyers

- Industry has experienced supply chain disruptions that have heightened buyer awareness

- You have the management bandwidth to implement improvements without distracting from core operations

If your likely buyer is acquiring for market access or technology, or if your current supply chain is reasonably diversified, these investments may not be justified.

Failure Modes and Implementation Risks

Not all supply chain improvement efforts succeed, and proceeding without understanding potential failure modes creates risk.

Failure Mode 1: Qualified suppliers can’t actually deliver when needed

- Probability: 20-30% based on manufacturing experience

- What happens: During actual disruptions, your “backup” suppliers may lack capacity or face the same constraints as your primary suppliers

- Mitigation: Test backup suppliers with small orders periodically; understand their other customer commitments; don’t rely solely on qualification without ongoing relationship maintenance

Failure Mode 2: Primary supplier relationship damage

- Probability: 10-20% in concentrated industries

- What happens: Current suppliers view diversification efforts as threats and become less cooperative, raise prices, or prioritize other customers

- Mitigation: Communicate diversification plans carefully; frame as risk management rather than dissatisfaction; consider involving relationship managers in conversations; pilot approaches with non-critical suppliers first

Failure Mode 3: Documentation becomes outdated

- Probability: High without dedicated maintenance

- What happens: Documentation created for due diligence becomes inaccurate within 6-12 months, potentially creating liability if buyers rely on it

- Mitigation: Assign ownership for documentation maintenance; build update processes into regular operational reviews; date all documentation clearly

Failure Mode 4: Cost increases exceed benefits

- Probability: Varies by industry and current state

- What happens: Diversification increases per-unit costs, dual supplier overhead, and management complexity beyond what can be recovered in valuation improvement

- Mitigation: Conduct realistic cost-benefit analysis before committing; implement incrementally and measure results; be willing to adjust or reverse course

Actionable Takeaways

Implementing supply chain resilience improvements before your exit process yields both immediate operational benefits and potential transaction advantages. Consider these priority actions, with realistic timelines and caveats:

Conduct a supplier concentration audit within the next 60-120 days depending on supply base complexity. Companies with fewer than 50 active suppliers can likely complete this in 60 days; those with 100+ suppliers should allocate 90-120 days. Calculate spend concentration across your top five suppliers and revenue dependency for critical inputs. This baseline assessment identifies vulnerabilities that warrant attention.

Implement a tiered supplier classification system that allocates relationship management investment appropriately. Focus resilience investments on Tier 1 strategic suppliers while maintaining efficient approaches for transactional relationships.

Begin contract improvement discussions with your top suppliers, but plan realistically. Assuming cooperative suppliers and standard terms, negotiations may take 2-4 months per supplier. For your top ten suppliers, plan 12-18 months total, potentially longer in industries with limited supplier options or during supply shortage periods. Suppliers may resist changes; consider offering quid pro quo such as extended payment terms or volume guarantees.

Identify and begin qualifying backup suppliers for your most critical inputs. Plan 4-6 months per supplier for manufacturing applications, longer for specialized components. Budget $3,000-$10,000 each in engineering and quality time. Recognize that qualification doesn’t guarantee availability during actual crises: maintain relationships with qualified backups even if you don’t place regular orders.

Create your supply chain documentation package including supplier master list, concentration analysis, contract summaries, and business continuity procedures, but only after addressing structural improvements. Documentation supports rather than substitutes for actual resilience.

Map supplier geography and develop diversification plans where concentration exists and diversification is feasible. Where diversification isn’t achievable, document alternative mitigations including safety stock, contingency plans, and insurance coverage. Be honest about constraints rather than claiming diversification that won’t withstand scrutiny.

Establish supplier financial monitoring processes, even if informal. Being able to describe how you track supplier stability during due diligence conversations signals operational awareness.

Communicate carefully with existing suppliers about diversification efforts. Proceed cautiously in concentrated industries where suppliers have leverage, and pilot approaches with non-critical suppliers before applying to strategic relationships.

Conclusion

Supply chain resilience has evolved from a secondary due diligence consideration to a meaningful focus area in today’s M&A environment. Buyers who experienced pandemic-era disruptions, or watched competitors struggle through them, increasingly approach supply chain evaluation with rigor, particularly PE buyers focused on operational stability.

For business owners planning exits in the coming years, this shift demands attention, but measured attention that accounts for your specific circumstances. The frameworks outlined here (tiered supplier classification, backup supplier qualification, geographic diversification where feasible, and thoughtful documentation) can address buyer concerns while strengthening your operations regardless of exit timing.

We’ve been careful in this article to acknowledge what we know and what we cannot prove. We cannot point to transaction databases showing specific valuation premiums for supply chain resilience. What we can say is that businesses demonstrating awareness of their supply chain vulnerabilities and credible approaches for managing them address buyer concerns more effectively than those caught unprepared during due diligence.

We encourage you to begin your supply chain resilience assessment now, well before you contemplate entering a sale process. Evaluate these investments against your specific buyer profile: if PE acquisition is likely, supply chain matters more than if strategic buyers are pursuing your customer relationships. Consider the full costs including ongoing expenses, not just initial investments. And recognize that supply chain improvement complements rather than substitutes for addressing fundamental value drivers like growth, profitability, and customer relationships.

In the post-pandemic M&A landscape, supply chain resilience isn’t just an operational metric: it’s a factor that influences buyer confidence and transaction dynamics. The question isn’t whether to address it, but how much investment makes sense given your specific circumstances, likely buyers, and exit timeline.